What Are Golf Balls Made Of: Material And Design Evolution

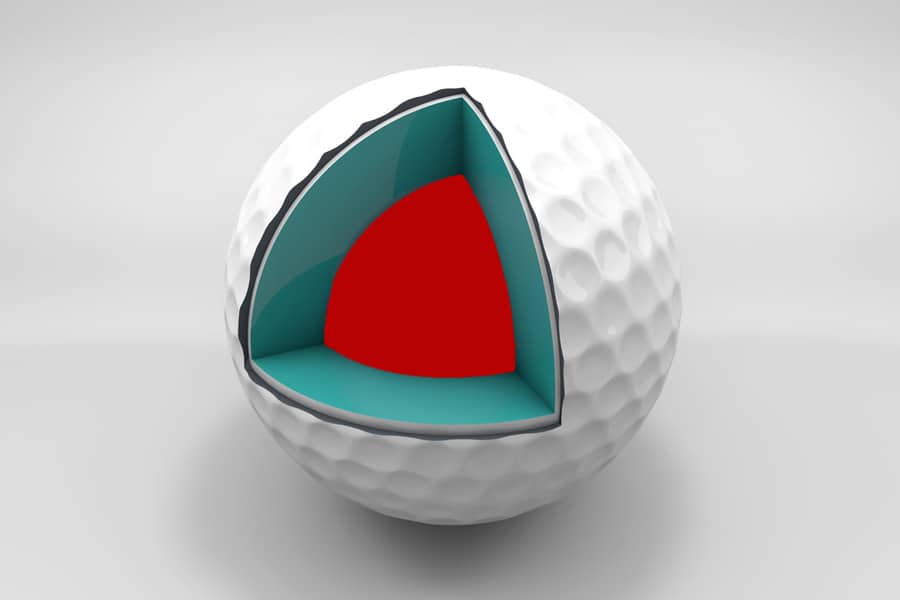

Golf balls have a number of features, including a core, layers, and cover, that all work together and affect their flight, spin, and feel. This article is a detailed analysis of how golf balls are made.

At first glance, you may find golf balls to be simple, but there is more than that you can even think of. Each dent, groove and dimple has its own significance to ensure precision on the course.

Commonly, a typical golf ball is dimpled and has a weight of 1.62 ounces with a diameter of 1.68 inches (42.67 mm). Let’s find in detail how a golf ball is made.

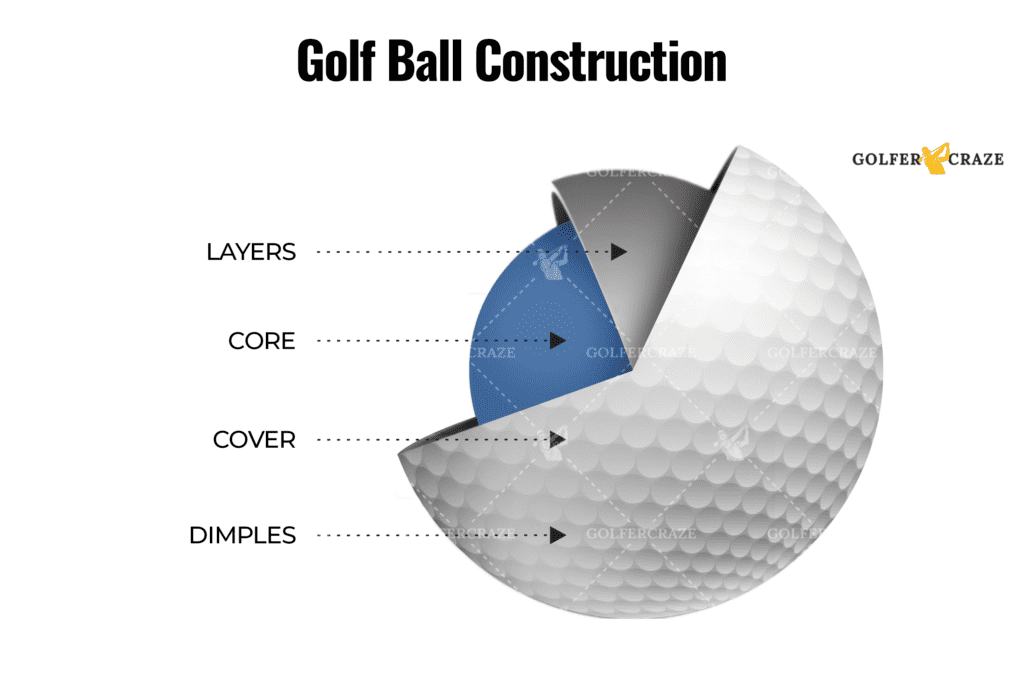

I. What are golf balls made of: Construction

The golf ball’s construction affects its flight, spin, and feel. Therefore, the ball’s structure is divided mainly into the core, the layers, the cover, and the dimples.

1. Core

A golf ball’s core is essential for its speed, distance, and spin in long and short games. The center of a golf ball is typically made of rubber or synthetic materials.

2. Layers

Golf balls are made of multiple layers consisting of a core, one middle layer or more, and an exterior coating. The extra layers create an additional spin that gives the player greater control over shots, incredibly when close to the hole.

3. Cover

The cover material is made of rubber, plastic, or ionomer resin. Moreover, the cover of the ball affects how it feels (softness) and the spin of the club head, especially in your short game.

4. Dimple Pattern

Every golf ball has its own number of dimples and a dimple pattern that helps it work its way. By adding dimples to the surface of a golf ball, its aerodynamic abilities are improved. This causes the airflow around the ball to create a tighter vortex, decreasing drag and increasing distance, speed, and lift.

II. History of golf balls

The game of golf has been around for centuries. And during that time, the golf ball has undergone a lot of changes. The first golf ball was made from hardwood, such as beech or boxwood. These early golf balls were difficult to hit and often got damaged easily.

Eventually, golfers started using golf balls that were made from leather. These golf balls were filled with feathers that were extracted from geese. The feathers helped make the golf ball lighter and easier to hit.

As time passed, golfers began experimenting with different materials for their golf balls. Eventually, golfers settled on a material called gutta-percha. Gutta-percha is a type of rubber derived from a tree’s sap.

The gutta-percha ball was much better than the previous golf balls that were made from hardwood and leather. They were easier to hit and didn’t get damaged as easily.

With the passage of time and after trying several golf ball coverings, golfers eventually settled on a material called balata. Balata is a type of latex derived from a tree’s sap.

Balata golf balls were much better than the previous golf balls that were made from gutta-percha. They were softer and had a better feel.

As time went on, golfers settled on a material called polyurethane. Polyurethane is a type of plastic that is known for being strong and durable.

Polyurethane golf ball is the best and most modern golf ball that has ever been made. It is much softer than the previous golf balls that were made from balata. This ball type also has a much better feel.

“The many different types of golf ball exist for a reason: to offer golfers, whatever their preference, a ball that suits the way they play their game.” – Steve Newell, author of The Golf Book

III. Types of golf balls

There are commonly four types of golf balls: one-piece balls, two-piece balls, three-piece balls, and four-piece balls, but before all that would happen, golf balls were used.

1. Wound Ball

There are two types of wound golf balls: those with a liquid center, where the core is filled with liquid, and those with a solid center, where the core is made from synthetic rubber.

These balls are made by winding a thin rubber thread around a small, hard center. After the golf balls are wound, they are wrapped in either a balata or surlyn cover on the top. The resulting characteristics of the Wound golf ball differ depending on which materials were used for the center and cover.

In general, wound balls perform better in spin rate than other golf balls but sacrifice distance and durability as a result. Additionally, they are not ideal for use in colder temperatures since losing distance when below 20°C is common with these golf balls.

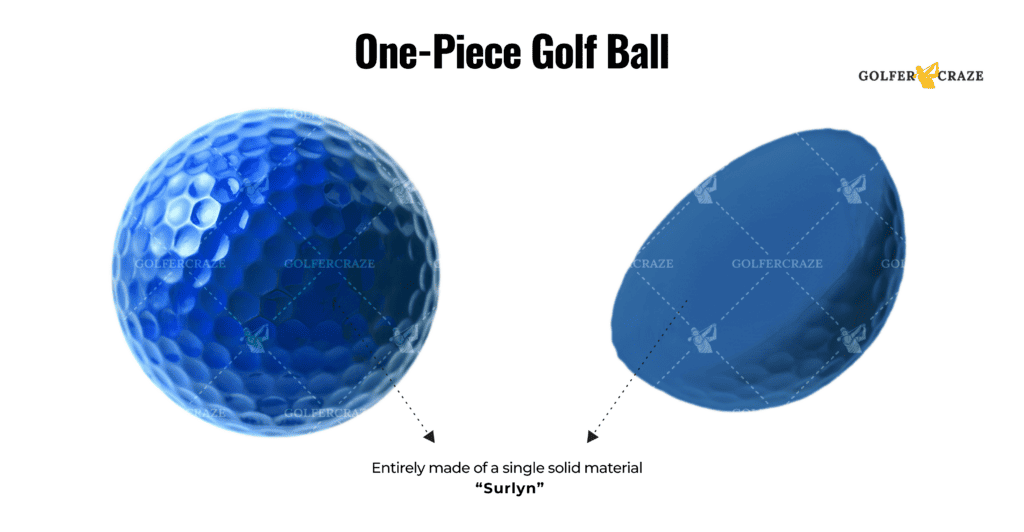

2. One-Piece Golf Balls

One-piece golf balls are made from a solid material named “Surlyn,” typically with fewer dimples than other golf balls to create lower spin rates.

These golf balls are the cheapest to produce because they’re constructed to last longer. They can commonly be found on mini golf courses and driving ranges.

The one-piece golf balls don’t travel as far as other types, but they’re perfect for practicing in the driving range or with a golf simulator.

Its soft feel, durability, and budget-friendliness make it a popular choice among novice golfers.

However, most people only use them during gameplay as they cannot hit the ball as far compared to the other models available. This is due to their low compression rate.

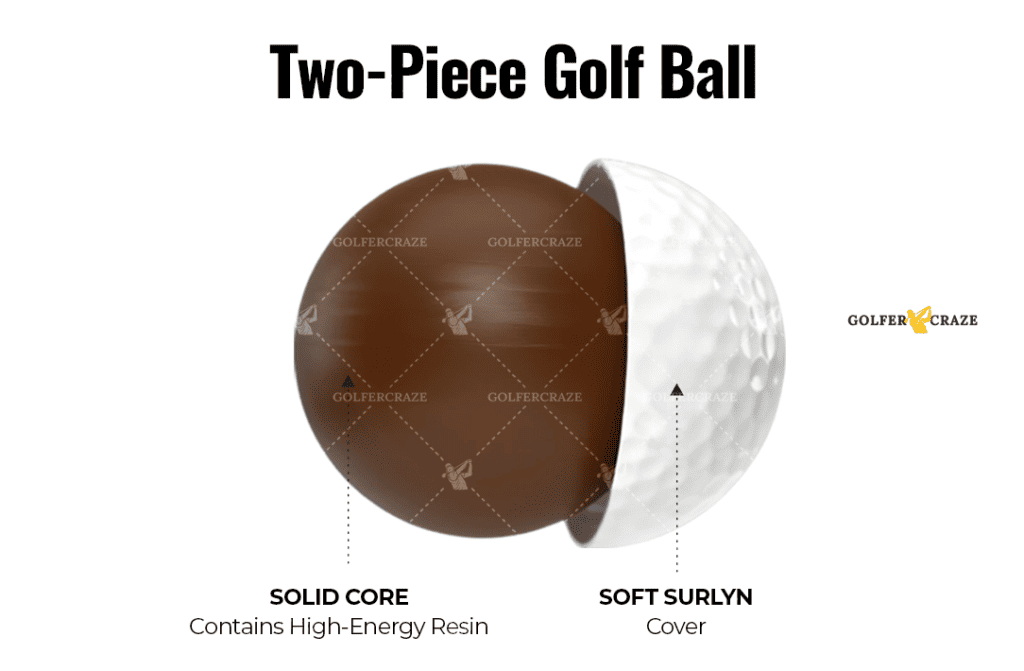

3. Two-Piece Golf Balls

Most golfers prefer two-piece balls because they provide long distances, a firmer feel, and excellent durability. High-handicapper players, seniors with slow swing speeds, and beginners mostly use this ball.

This type of golf ball design is used to minimize slicing and hooking, giving it more distance. It has a thin two-layer (rubber and plastic cover) with a solid core containing high-energy resin or acrylate. The tough outer layer protects the inner core, while the Surlyn covering gives it extra durability.

The two-piece construction model increases the amount of energy the club can transfer to the ball. This, in turn, gives more power to shots and moves the ball forward for greater distance.

However, it is essential to note that these models are more challenging to control when compared with softer feel options and do not spin as much. The top three two-piece models on the market are Titleist Velocity, Srixon Soft Feel, Volvik Power Soft, and Bridgestone e6.

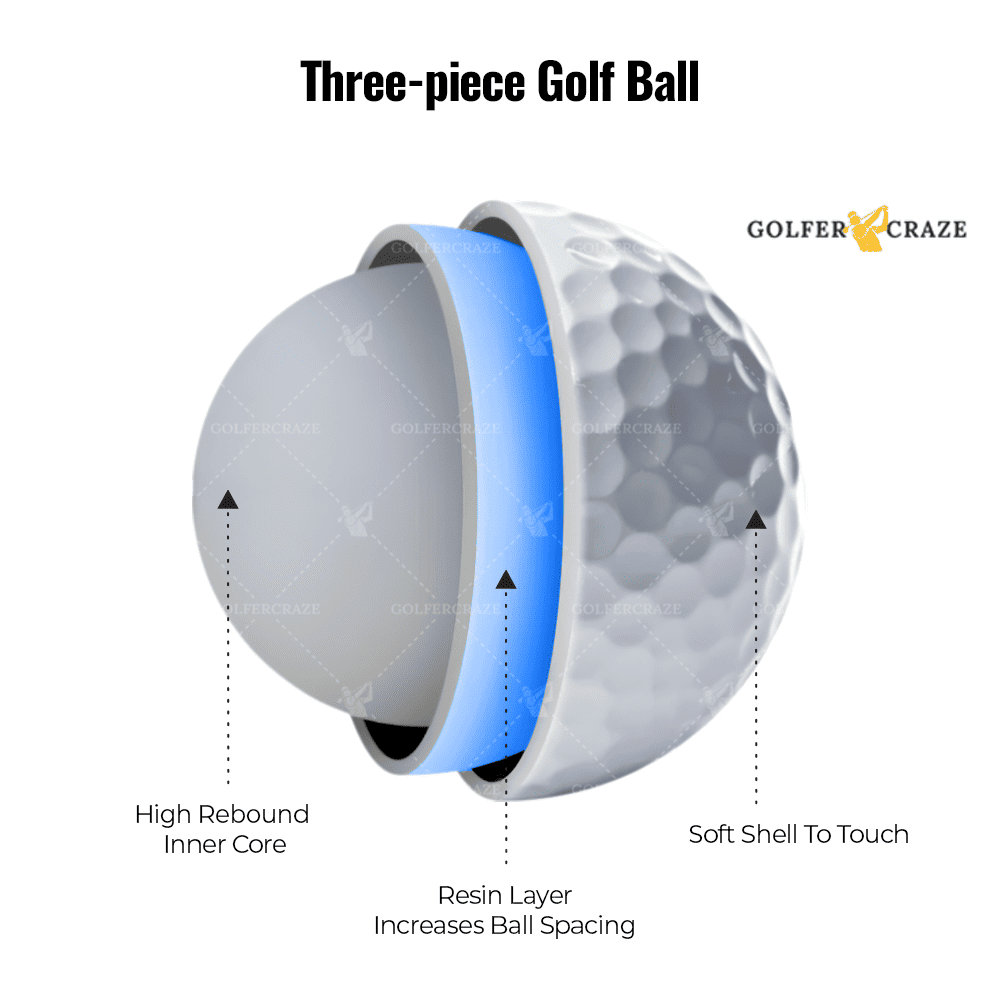

4. Three-piece Golf Balls

A three-piece ball contains three layers: a liquid or solid rubber core and a layer of liquid-enhanced rubber. It is then molded with a cover made from durable urethane cover, Surlyn, or balata.

The Titleist Pro V1, Bridgestone e12, and the Srixon Z-Star are some of the best three-piece golf balls on the market. These models come with better spin properties and have a softer feel, which gives the player greater control over the ball’s flight and around the greens.

When the golf ball manufacturer creates the ball’s spin advantages, it results in higher customized performance for that driver when compared to wedges or irons.

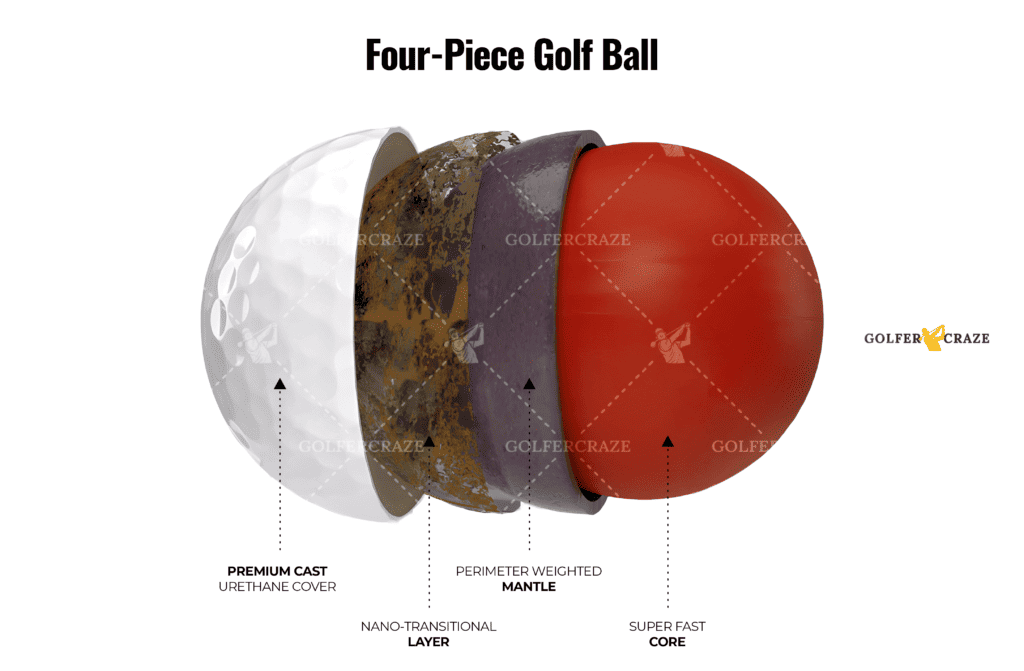

5. Four-Piece Golf Balls

The purpose of each layer in this model is to work together and provide the softest feel while also extending hitting. The innermost core contains a solid rubber center which will help produce great distance with the help of a driver.

The next layer aids in transforming energy from strikes to the golf ball core. The following extra layer creates a mixed iron feel that spins around the green when hit.

The outer cover is what gives the ball its feel. This layer contains around 300 to 400 dimples and is made using Urethane, which is soft yet durable. These options travel similar distances to the longest golf balls on the market.

The most popular four-piece balls in the golf ball market are Titleist Pro V1x, Callaway Chrome Soft, and Srixon Z-Star XV.

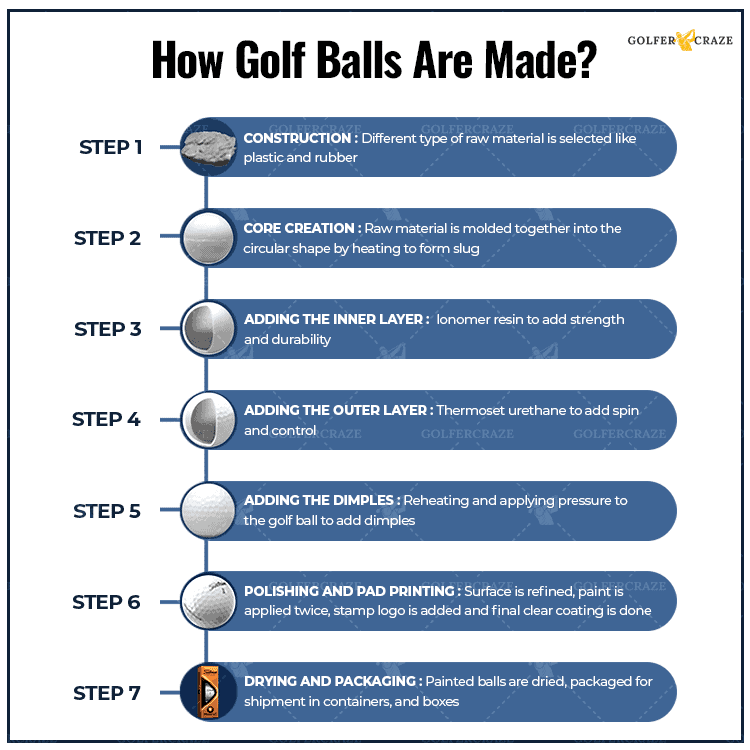

IV. Steps on how golf balls are made?

The goal of golf is to hit the ball with a club and make it land in the hole. But how exactly are golf balls made?

Just like many objects we use daily, golf balls are created through a manufacturing process. Here are the steps on how golf balls are made:

1. Creating the Core, Layers, Cover, and Dimples (Construction)

The very first layer of the golf ball is the core. The core is typically made from a rubber compound. In order to create the synthetic rubber compound, golf ball manufacturers first start with liquid polybutadiene. This liquid is then mixed with other ingredients (such as zinc oxide and stearic acid) in order to create a solid core.

- Adding the Inner Layer

Once the core has been created, manufacturers will then add an inner layer.

This inner layer is typically made from a material called ionomer resin. Ionomer resin is a type of plastic that contains metal ions. Adding this inner layer helps to add strength and durability to the golf ball.

- Adding the Outer Layer

After the inner layer has been added, manufacturers then add an outer layer. This outer layer is typically made from a material called thermoset urethane. Thermoset urethane is a type of plastic that is known for being strong and durable. Adding this outer layer helps to add spin and control to the golf ball.

- Adding the Dimples

After the cover has been added, manufacturers add dimples – which are the small indentations that help to add spin and control to the golf ball.

2. Injection or Compression Molding

Injection molding and compression molding are used to form the covers and dimples on the ball. Both processes use a combination of heat and pressure, with temperatures up to 300°F and pressures up to one ton.

The number of pieces of a ball determine how long it’ll take to be completed. For example, two-piece balls usually only take a day, but three-piece balls could sometimes take weeks.

3. Pad Printing

Most golf balls have some logo or design printed on the exterior, like a company name or logo. This design is applied with pad printing, which uses a large stamp that gets covered in ink and then transfers the ink to the surface of the ball. The ball is then coated with polyurethane to seal the design and protect it from any damage.

4. Packaging

The golf ball is now packaged and ready to be shipped to a retailer or eCommerce company!

V. Benefits of using the right golf balls

Using the correct type of golf ball can improve your game. Beginners should use two-piece balls because they are the easiest to hit. More advanced players should use three-piece or four-piece balls because they offer more control. If you are looking to add more spin to your shots, choose a ball with a softer cover. If you want more distance, choose a ball with a harder cover.

Conclusion

Golf balls are small, round, dimpled balls made of rubber, plastic, or synthetic materials. The construction of a golf ball affects its flight, spin, and feel. Three main types of golf balls include two-piece balls, three-piece balls, and four-piece balls. Using the correct type of golf ball can improve your game. Choose a ball based on your skill level and get desired results.